产品说明

一般描述

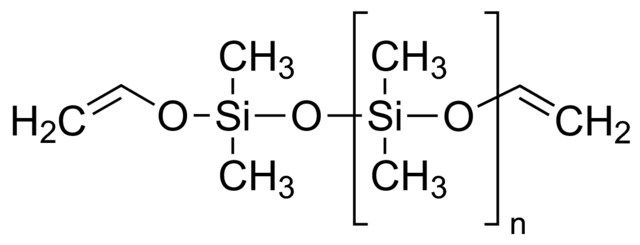

作为一种基于硅酮的弹性体组件,SYLGARD®184是一种双组分体系,即与所述聚合物基质交连的聚合物和固体剂。合成的复合材料为聚二甲硅氧烷(PDMS),室温下其抗拉强度(UTS)为5.2 MPa左右且肖氏硬度(shore)大约为44。固化温度越高,抗拉强度越大,硬度越大,杨氏模量(E)越大。′

应用

基于SYLGARD®184的PDMS可用于各种应用的软刻蚀技术,例如微流体、微机电系统(MEMS)及其他柔性电子设备等。此外,还应用于疏水性PDMS膜,可用作光伏电池的防潮膜。

包装

方便的泡罩包装预称重单体和固化剂。其中分两部分透明袋包装,单独隔开、不会混合。

SYLGARD 184硅树脂弹性体试剂盒由基础/固化剂以10(基础):1(固化剂)重量比混合组成,用于手动混合。

制备说明

PREPARING SURFACES - In applications requiring adhesion, priming will be required for many of the silicone encapsulants. For best results, the primer should be applied in a very thin, uniform coating and then wiped off after application. After application, it should be thoroughly cured prior to application of the silicone elastomer. Additional instructions for primer usage can be found in the information sheets specific to the individual primers.

PROCESSING/CURING - Thoroughly mixed the silicone encapsulant may be poured/dispensed directly into the container in which it is to be cured. Care should be taken to minimize air entrapment. When practical, pouring/dispensing should be done under vacuum, particularly if the component being potted or encapsulated has many small voids. If this technique cannot be used, the unit should be evacuated after the silicone encapsulant has been poured/ dispensed. Dow silicone encapsulants may be either room temperature (25 ℃ /77°F) or heat cured. Room temperature cure encapsulants may also be heat accelerated for faster cure. Ideal cure conditions for each product are given in the product selection table.

POT LIFE AND CURE RATE - Cure reaction begins with the mixing process. Initially, cure is evidenced by a gradual increase in viscosity, followed by gelation and conversion to a solid elastomer. Pot life is defined as the time required for viscosity to double after base and curing agent are mixed and is highly temperature and application dependent. Please refer to the data table.

USEFUL TEMPERATURE RANGES - For most uses, silicone elastomers should be operational over a temperature range of -45 to 200℃ (-49 to 392°F) for long periods of time. However, at both the low and high temperature ends of the spectrum, behavior of the materials and performance in particular applications can become more complex and require additional considerations and should be adequately tested for the particular end-use environment. For low temperature performance, thermal cycling to conditions such as -55℃ (-67°F) may be possible, but performance should be verified for your parts or assemblies. Factors that may influence performance are configuration and stress sensitivity of components, cooling rates and hold times, and prior temperature history. At the high-temperature end, the durability of the cured silicone elastomer is time and temperature dependent. As expected, the higher the temperature, the shorter the time the material will remain useable.

COMPATIBILITY - Certain materials, chemicals, curing agents and plasticizers can inhibit the cure of addition cure gels. Most notable of these include: Organotin and other organometallic compounds, silicone rubber containing organotin catalyst, sulfur, polysulfides, polysulfones or other sulfur containing materials, unsaturated hydrocarbon plasticizers, and some solder flux residues. If a substrate or material is questionable with respect to potentially causing inhibition of cure, it is recommended that a small scale compatibility test be run to ascertain suitability in a given application. The presence of liquid or uncured product at the interface between the questionable substrate and the cured gel indicates incompatibility and inhibition of cure.

法律信息

Sylgard is a registered trademark of The Dow Chemical Company or an affiliated company of Dow

基本信息

| NACRES | NA.23 |

产品性质

| 质量水平 | 100 |

| 形式 | liquid |

安全信息

| 象形图 |  |

| 警示用语: | Warning |

| 危险声明 | H315 - H319 - H335 |

| 预防措施声明 | P261 - P264 - P271 - P280 - P302 + P352 - P305 + P351 + P338 |

| 危险分类 | Eye Irrit. 2 - Skin Irrit. 2 - STOT SE 3 |

| 靶器官 | Respiratory system |

| 储存分类代码 | 10 - Combustible liquids |

| WGK | WGK 3 |

| 闪点(F) | 250.0 °F |

| 闪点(C) | 121.11 ℃ |